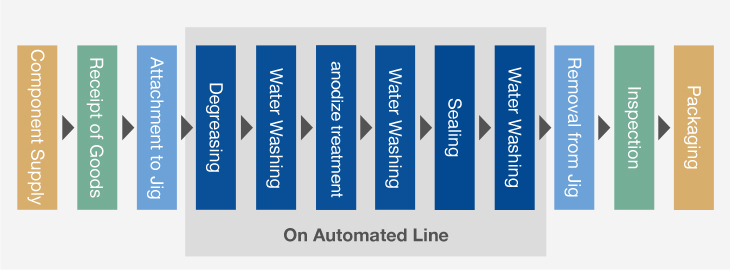

An introduction to the processes involved in anodize treatment once an order is placed.

The customer’s goods are inspected upon reception and given an identification tag. This identification tag contains a full list of relevant customer information and treatment conditions needed for each stage from intake to shipment.

Products are attached to the appropriate jig. All jigs are independently designed exclusively for in-house use.

Contaminants such as cutting oil and anti-rust oil are removed to make the surface as clean as possible.

Acid applied during the previous process is washed away.

Anodize treatment offering stable quality is applied on a computer-controlled fully automated line.

Acid applied during the previous process is washed away.

Any holes generated in the membrane are sealed.

Acid applied during the previous process is washed away.

The product is removed from the jig and cleaned to finish.

All units are visually inspected. A designated number of samples are also tested for membrane thickness and hardness as per customer request.